42HS48 NEMA17 5.0kg-cm 1.8 Degree 2 Phase Industrial Grade hybrid Stepper Motor

- Product SKU: LGSTM009

Need Volume Discounts? Deals are specially designed for you. Click here

Need Customization? Provide us more details Click here

Specification

Description

The 42HS48 NEMA17 Hybrid Stepper Motor is a high-torque motor with a 1.8° step angle, designed to offer reliable performance and precision in industrial applications. With a holding torque of 5.0kg-cm, this motor provides enhanced power for tasks requiring accurate control and strong force. Its compact NEMA17 frame makes it suitable for space-constrained applications, while its robust construction ensures durability under continuous usage. This two-phase stepper motor is optimized for demanding use cases, including CNC machines, robotics, and precision automation.

Features:

High Torque: 5.0kg-cm of holding torque provides the strength needed for heavier loads and industrial use.Standard Step Angle: A 1.8° step angle offers precise control over movement and positioning.

Compact NEMA17 Frame: Fits into tight spaces without sacrificing performance or strength.

Durable Construction: Designed for long-term use in rugged industrial environments.

Smooth Operation: Two-phase operation ensures reliable performance with minimal noise or vibration.

Low Vibration: Operates with reduced vibration, making it suitable for precision tasks.

Applications:

CNC Machines: Provides precise motion control for milling, drilling, and cutting machines.3D Printers: Ensures accurate control of the extruder or print bed, offering fine movement for detailed printing.

Robotics: Ideal for controlling robotic arms, wheels, or grippers where high torque and precision are required.

Automation Systems: Suitable for conveyor belts, pick-and-place machines, and other automation tasks that require consistent movement.

Medical Devices: Provides the necessary precision for various medical devices, including diagnostic and treatment equipment.

Advantages:

High Torque: With 5.0kg-cm holding torque, it can handle heavier loads than other NEMA17 motors.Accurate Control: The 1.8° step angle allows for detailed and smooth control of movements, making it ideal for precision tasks.

Reliable and Durable: Built for long-term use, especially in industrial and demanding environments.

Versatile Applications: Suitable for a wide range of applications, including robotics, CNC machines, and 3D printing.

Disadvantages:

Power Consumption: Stepper motors continuously draw power, even when stationary, leading to higher energy use compared to other motor types.Heat Generation: The motor may generate significant heat under high loads and continuous operation, requiring cooling mechanisms.

Reduced Efficiency at High Speeds: Like most stepper motors, efficiency and torque may decrease at higher speeds.

Compatible Accessories

Technical Details

- No. of Phase : 2

- Step Angle: 1.8°

- Holding Torque : 5.0 kg.cm

- Shaft type : D

- Insulation resistance : 100MΩmin. (500V DC)

- Insulation Class: B (130°);80K max.

- Temperature Rise: 80°C max.

- Ambient Temperature : -20°C - +50°C

- Phase Voltage : 2.8 V

- Phase Current : 1.68 A

- Phase Resistance : 1.65 Ω±0.1(20°C)

- Phase Inductance : 2.8 mH±20%(1kHz 1V RMS)

- Dielectric Strength : 500VAC for 1min.

- Shaft Radial Play : 0.02Max (450g-load)

- Shaft Axial Play : 0.08Max (450g-load)

- Detatchable wire, D Shaft

- Max. Radial Force : 28N (20mm from the flange)

- Max Axial Force : 10N

Physical Attribute

- Weight (gm) : 360

- Wire length : 1 meter

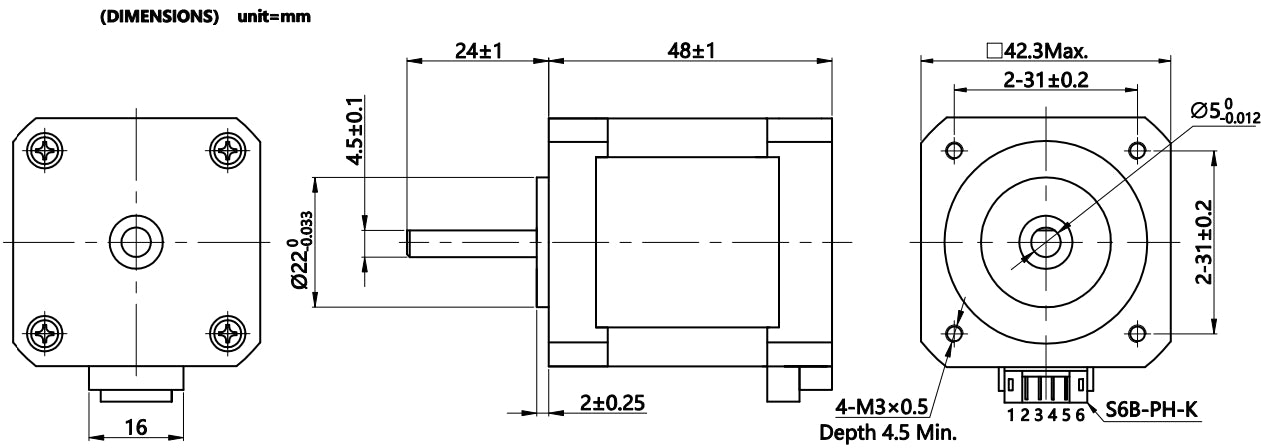

Dimensional Drawing

Wiring Diagram

Package Includes

- 1 x 42HS48 NEMA17 5.0kg-cm 1.8 Degree 2 Phase Industrial Grade Hybrid Stepper Motor